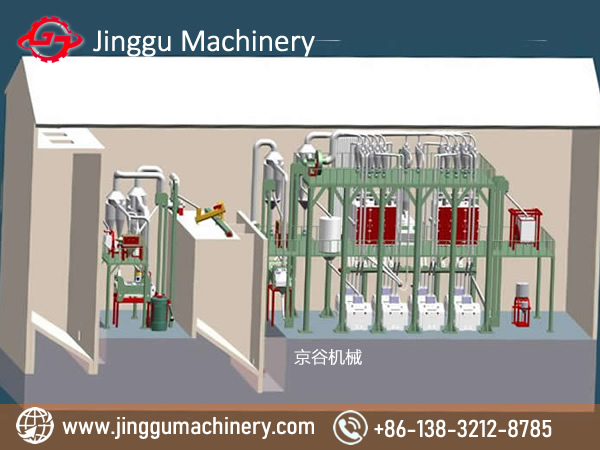

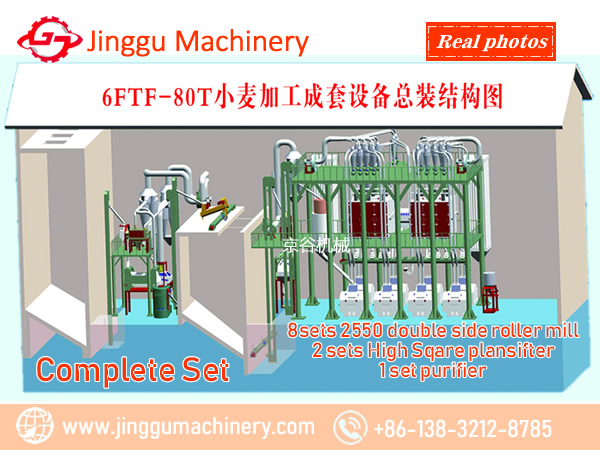

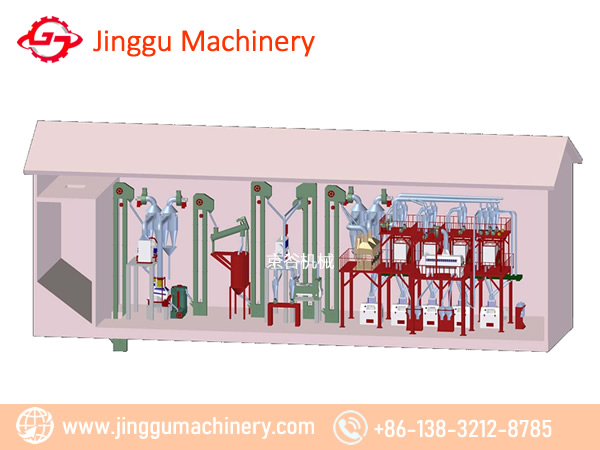

Complete set of wheat flour mill can be divided into three parts:

1. Cleaning part :

To clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, wheat was bitten by insect and so on. This section is to prepare for milling part and to protect the machinery as well.

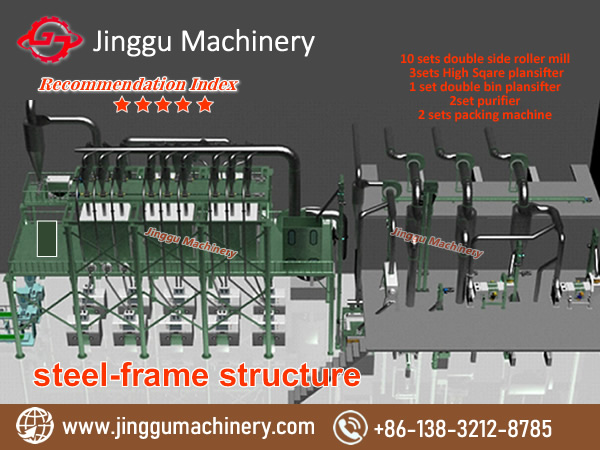

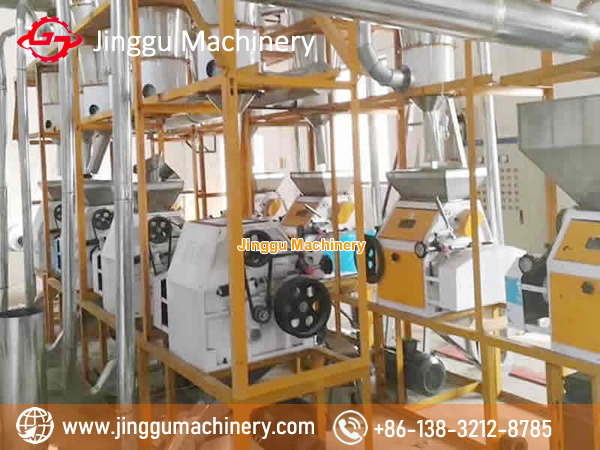

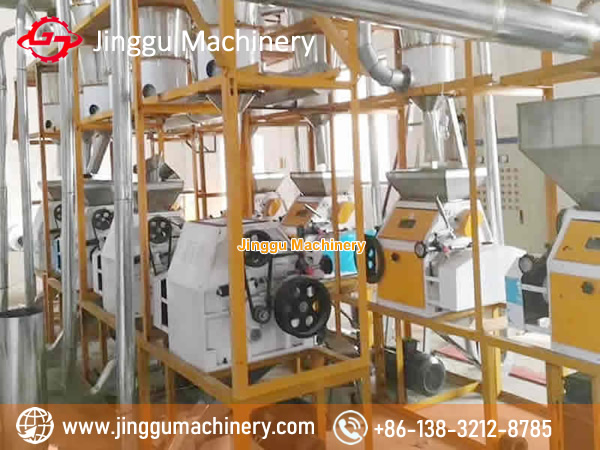

2. Milling part:

The second step, to mill the grain and separate the flour, bran and other by-product:

(1) Mill: mill the grain to break the integrity by the roller moving.

(2) Sifter: to separa te the flour,bran and other by-product, also separate large size and small size to ensure flour quality

3. Packing part:

The third step, the packing machine can be manual or automatic weighting and packing.

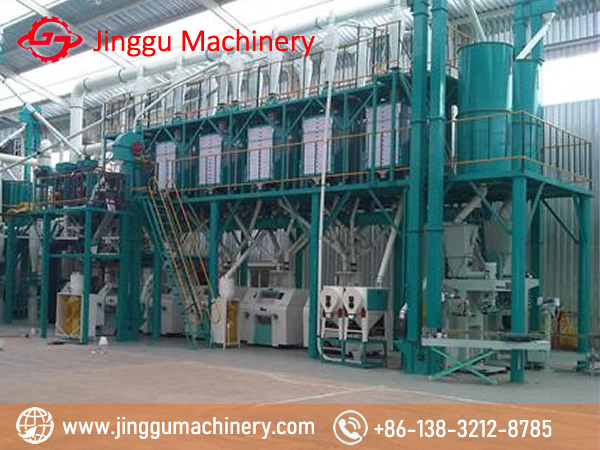

Introduction of 36t wheat flour milling machine:

Milling Techniques: 4break-3reduction -1S-1bran brushing;(2-6F2240 roller mill, 6-6F2235 roller mill,1-High Sqare plansifter,1-conveyor,1-bran brusher,1-feeder)

Cleaning Techniques:2 sifting-2 scouring-2 destoning-2 magnetic separating-1 washing-1 air separating (high efficiency vibrating sieve, scourer, bucket elevator, destoner, low pressure blower,washing machine)

Products and extraction rate (%):Grade 1 flour: 60%~68%, Standard flour: 78%~83%

Flour quality:Better than GB1355-88 (National standard of China)