Working principle of combined cleaning machine

As we know, there are many impurities in raw maize, we need to make it clean before we process maize into flour, so we need some cleaning machine.

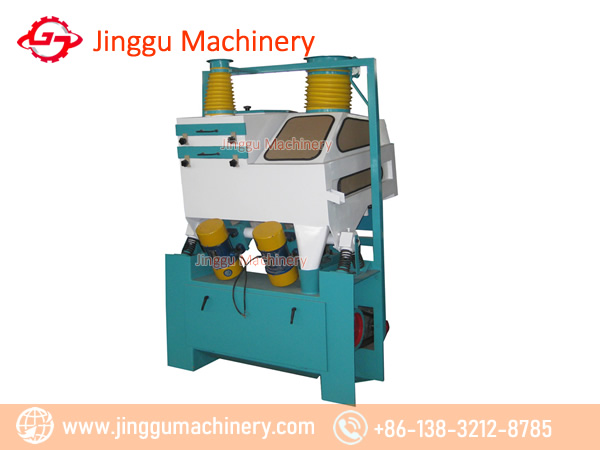

combined cleaning machine which is made up of high efficiency vibrating machine,destoner, scourer. They have different function.

Now we talk about the function of each part.

No. One: high efficiency vibrating sieve

High efficiency vibrating sieve is used for removing big and small impurities from maize.

It has two layers of screen surface; the first layer screen surface has big size hole which maize can pass through, and the second layer screen surface has small size hole which only let small impurities pass through, if so, maize will be kept between the first layer and the second layer. And then go to destoner.

Here I indicate the exit of big impurities and the exit of small impurities.

No. Two: destoner

Destoner system is made up of (consist of) blower and detoner.

Blower generate negative pressure which suck light impurities and then blow it into cyclone, the impurities will be discharged by cyclone.

Destoner also have two layers of screen surfaces, maize pass through first layer, and be kept on the second layer, enter into maize scourer.

Big impurity will be kept on the first layer and then discharged by exit of big impurities;

Stones will move up and be discharged by exit;

No. three:Maize scourer

The maize beat maize and let black point fall out from germ,improve the quality of final product. The black point and small-light impurities pass through the round sieve and be discharged out.